-

Fluorine removal chelating resin

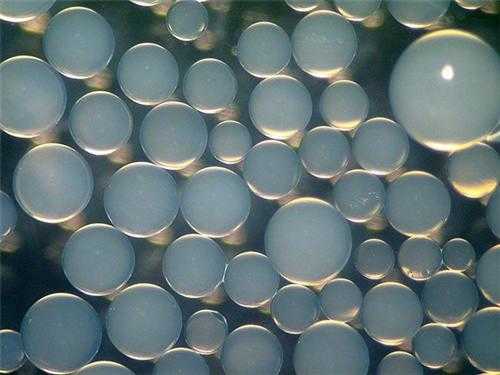

SY-901 defluorination resin is a polymer that introduces active rare earth element groups onto the styrene divinylbenzene framework and undergoes surface oxidation heat treatment. It is also a type of chelating resin. The unique structure of SY-901 defluorination resin helps to form stable complexes with fluoride ions in water, reducing the fluoride ion content in water from tens or hundreds of pp...

-

The pattern of ion exchange resins in the world today

Ion exchange resins are largely driven by the needs of industry. Industrial applications for ion exchange resins include water treatment, chemical processing, pharmaceutical production, food and beverage processing, and more. Common uses of ion exchange resins include removing dissolved salts from water, softening hard water, purifying chemicals and pharmaceuticals, recovering valuable metals from...

-

Development of ion exchange resins in the United States

Ion exchange resins have been developed in the United States since the 1950s. Early research focused on developing cation exchange resins for water softening and deionization applications. The first commercial ion exchange resin was introduced in 1956 by Dow Chemical Company. Since then, ion exchange resins have been used in a variety of applications, including water treatment, food processing, ph...

-

How to prevent resin pollution? How to deal with the contaminated resin?

What is the cause of resin contamination? The ion exchange resin is invaded by the suspended solids, colloids, organics, microorganisms, heavy metals, oxides and other harmful impurities dissolved in the water during use, which makes the performance of the resin significantly worse. In one case, the exchange capacity of the resin is significantly reduced and regeneration is difficult due to the bl...

-

Filling and Pretreatment of Anion and Cation Resins in Mixed Bed

The specific operations are as follows: Clean the bed and put water 1-2 meters deep (ensure that the water surface is higher than the resin layer): 1. The design height shall be filled with resin (the final height of resin shall be subject to re ecology). 2. After installing the cation exchange resin, backwash to make the resin surface smooth, and then install the anion exchange resin; Two steps h...

-

How to pretreat anion exchange resin?

2. Pretreatment of anion resin: 2.1 After the anion exchange resin is filled, backwash shall be carried out first to ensure 80% backwashing expansion rate to remove impurities and fine resin particles until the backwashing effluent is clear. 2.2 Feed 2-3% NaOH solution at a flow rate of 4m/h. When the outlet concentration reaches 1.5-2%, stop feeding and soak for more than 8 hours, and then rinse ...

-

How to pretreat cation exchange resin?

1. Pretreatment of cation exchange resin: 1.1 After the cation resin is filled, backwash shall be carried out first to ensure 80% backwash expansion rate to remove impurities and fine resin particles until the backwash effluent is clear, colorless, tasteless and foam free. 1.2. Fill 3-4% HCl solution, 4m/h, when the outlet concentration reaches 1.5-2%, stop filling and soak for more than 8 hours, ...

-

How to clean ion exchange resin ?

Before using the ion exchange resin purchased in the market, in order to prevent impurities in the resin from polluting the water quality, the resin needs to be pretreated. The following steps are for pretreatment: 1. First, clean the resin with hot water. The cation resin can be cleaned with 70-80 ℃ hot water. The heat resistance of the anion resin is poor. Generally, 50-60 ℃ hot water is used. T...

-

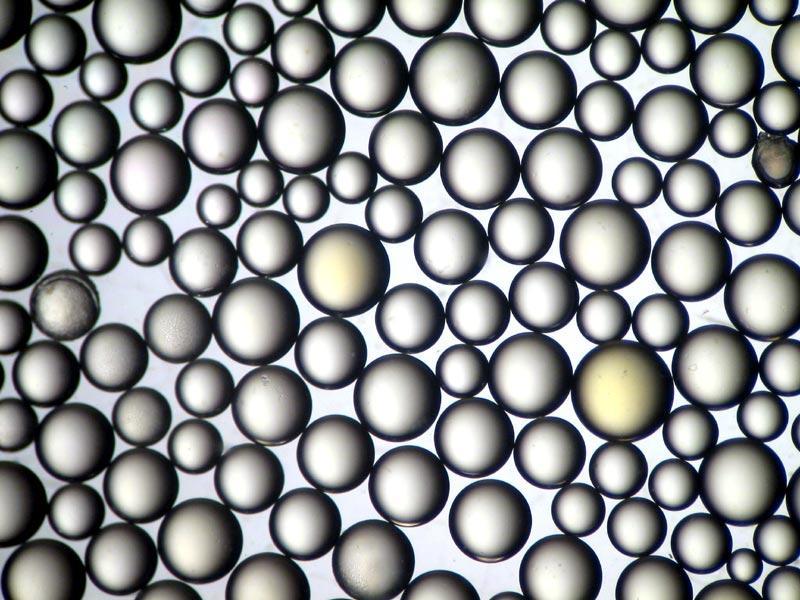

What is the crosslinking degree of ion exchange resin?

Crosslinking degree is one of the important properties of styrene resin. It is the network structure of the framework of ion exchange resin polymerized by various organic materials, expressed in percentage. Crosslinking degree refers to the mass percentage of divinylbenzene (commonly known as "crosslinking agent") contained in styrene resin. That is, if the crosslinking degree=divinylbenzene mass/...

-

Ion exchange equilibrium and ion exchange selectivity

The separation function of ion exchange resin for mixed ions (including inorganic ions and organic ions) is based on its ion exchange selectivity. In a closed system, the fixed ion (A) of the ion exchange resin exchanges with the ion (B) in the solution, and can reach equilibrium after a certain time. The selectivity of ion exchange resin is affected by many factors, such as the nature of chemical...

English

English